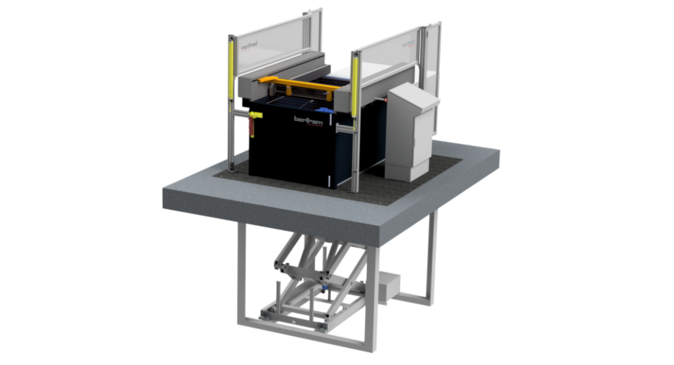

Rejection and dividing systems are an important component for controlling the product flow and for inline quality assurance, especially in glassworks and bottling plants in the beverage industry. Due to the high production speeds, we use powerful controls, servo technology and precise industrial image processing.

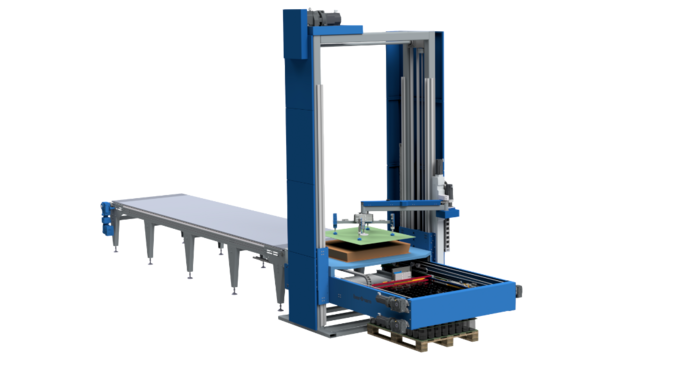

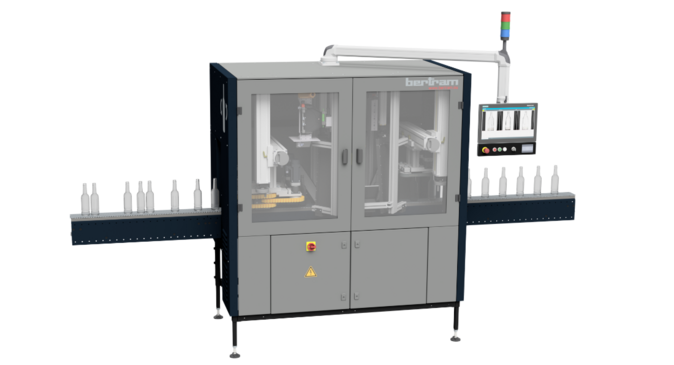

Different systems are used depending on the production speed and the shape of the container. Simple and proven, but not particularly precise, are blow-out systems. They are therefore particularly suitable for rejecting faulty containers after a testing machine, because here it is not relevant whether a container tips over or not.

The situation is completely different when it comes to controlling the product flow, for example for load distribution or in assortment production. For this purpose, we have developed two of our own rejection systems, which can be used very flexibly as compact and easy-to-integrate units.

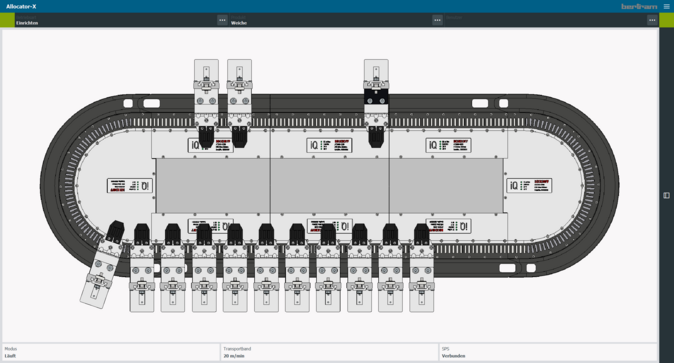

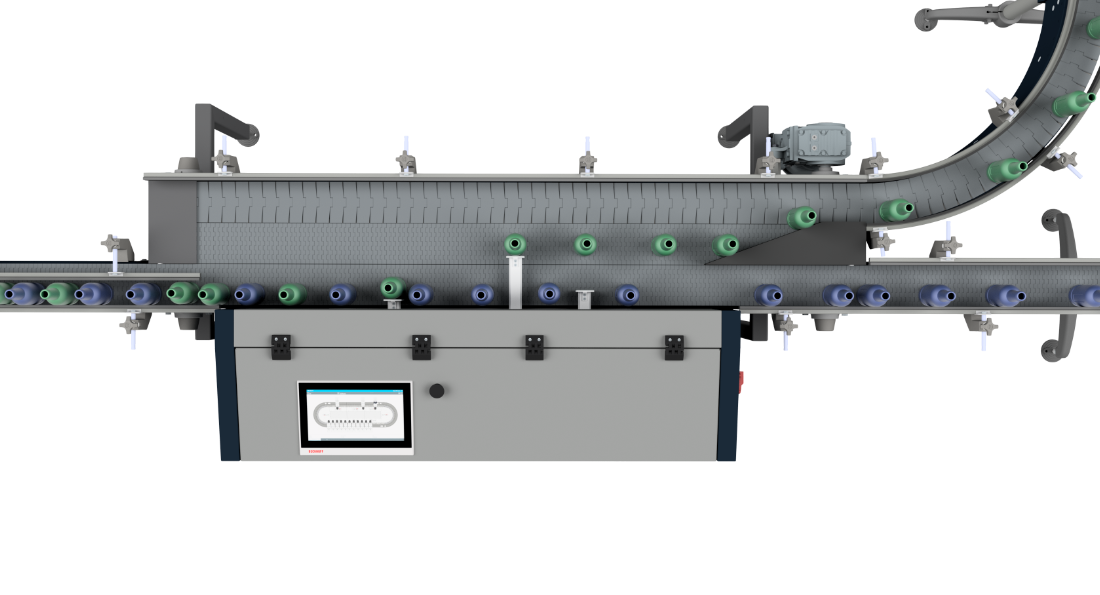

The operating principle of our allocator is based on a rotary, eccentric rejection body, with which the containers are guided from one conveyor belt to an adjacent belt.

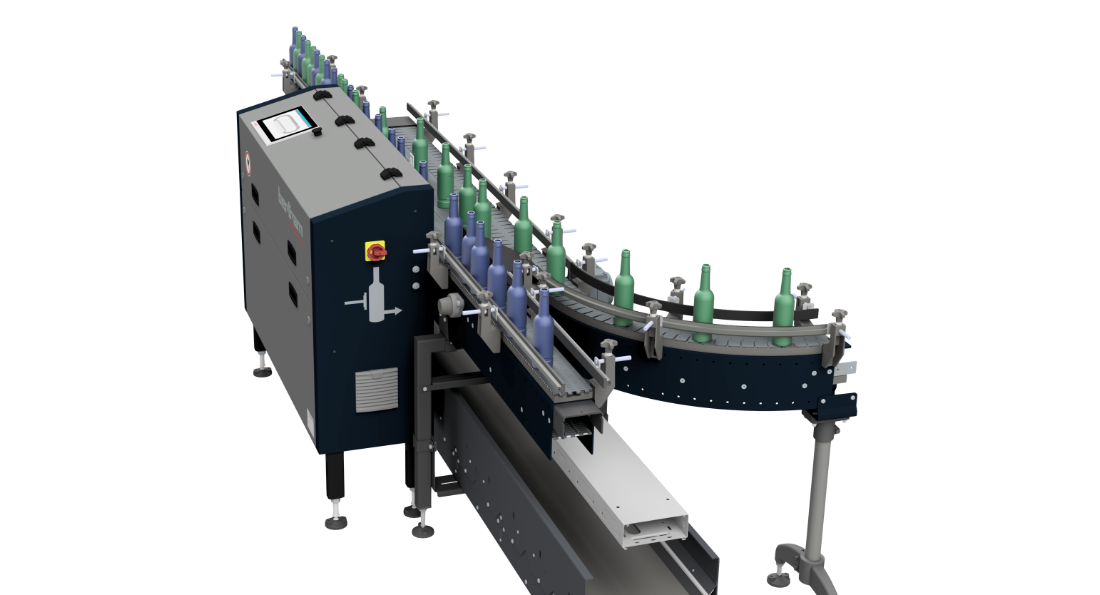

The Allocator X is used when the transfer has to be particularly smooth and even, e.g. when the containers have a high centre of gravity and/or a small contact area and would therefore easily fall over if the direction were changed. With this system, individual linear motors synchronise with the product to be discharged and push it gently onto the conveyor belt next to it. This system is also suitable for splitting from one conveyor track to three tracks.