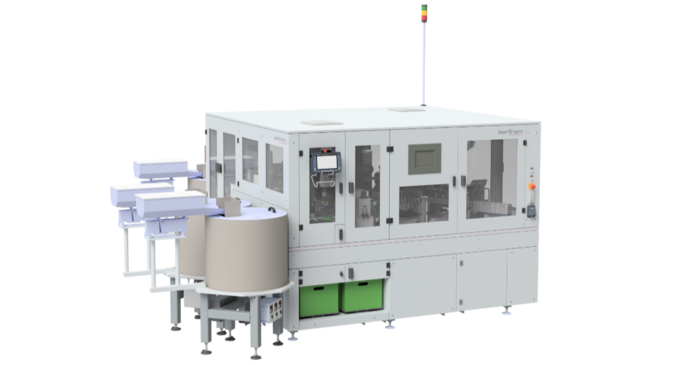

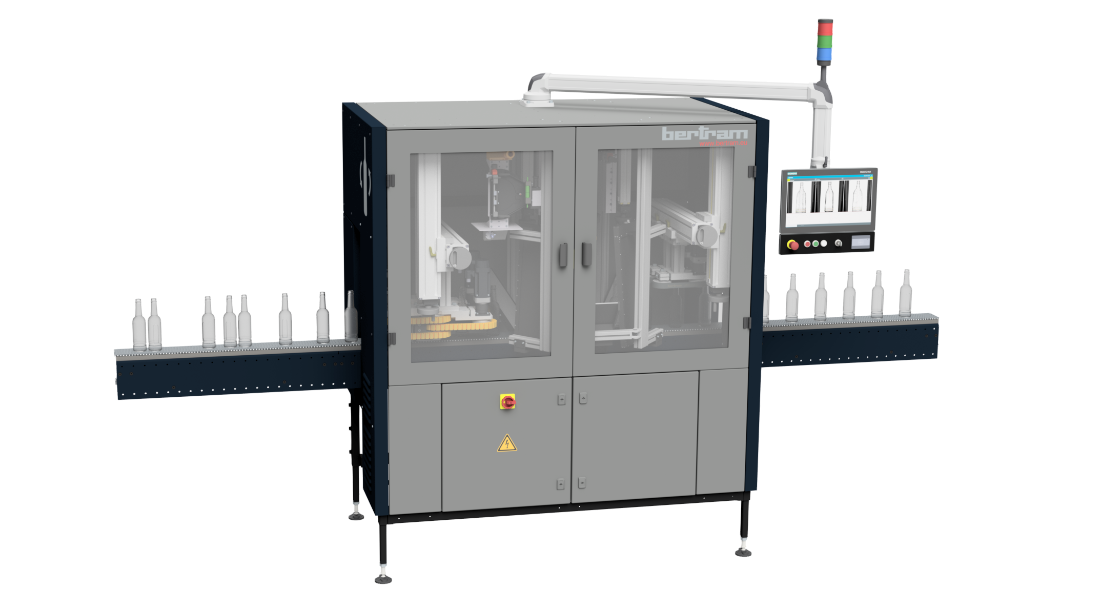

Today, containers, especially glass bottles, are becoming more and more individual. This concerns on the one hand the outer shape and on the other hand embossings on the surface. To avoid problems caused by this, such containers are aligned before the testing machines and/or before palletising so that the relevant characteristic always points in the same direction.

This is done in three steps:

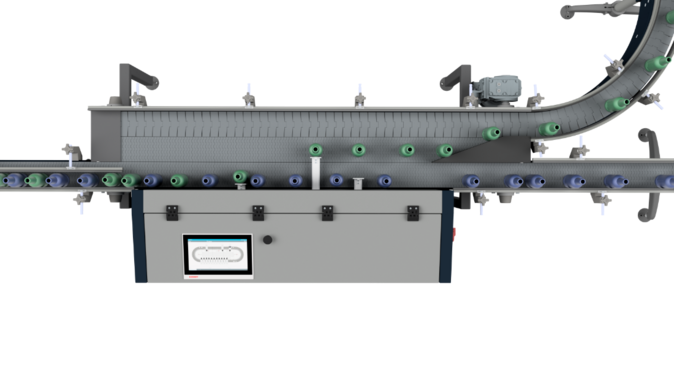

With an allocation, a distance is first created between the containers.

Then a 360° image of the container is taken. Our image processing software detects the orientation of the relevant feature and calculates the deviation from the target position.

In the third step, this deviation is corrected via two belts with servo drive. This happens synchronously with the belt speed so that the position of the container does not change relative to the transport. In this way, the "orientator with detection system" brings up to 500 containers per minute exactly into position.