Automated inspection

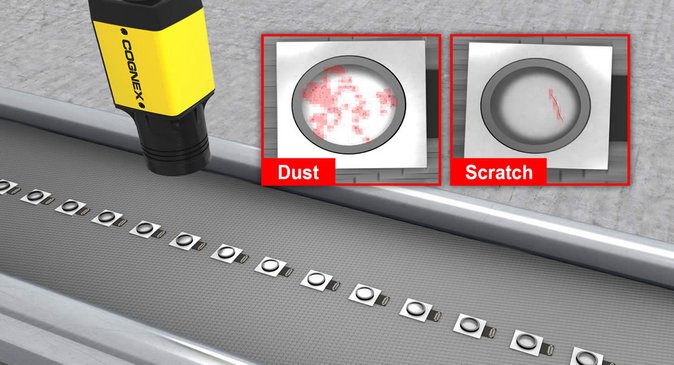

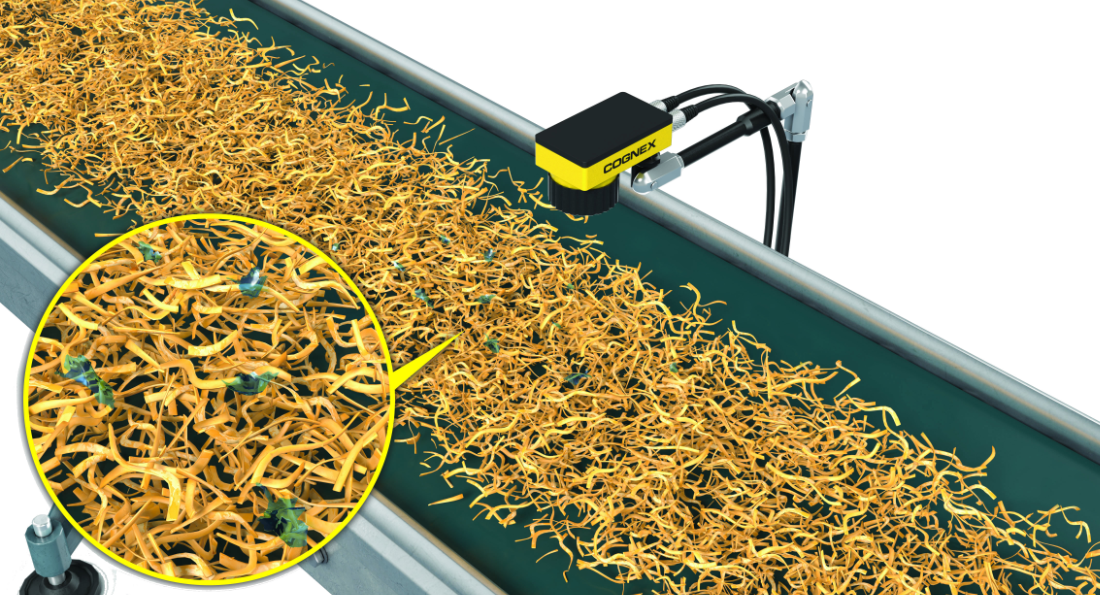

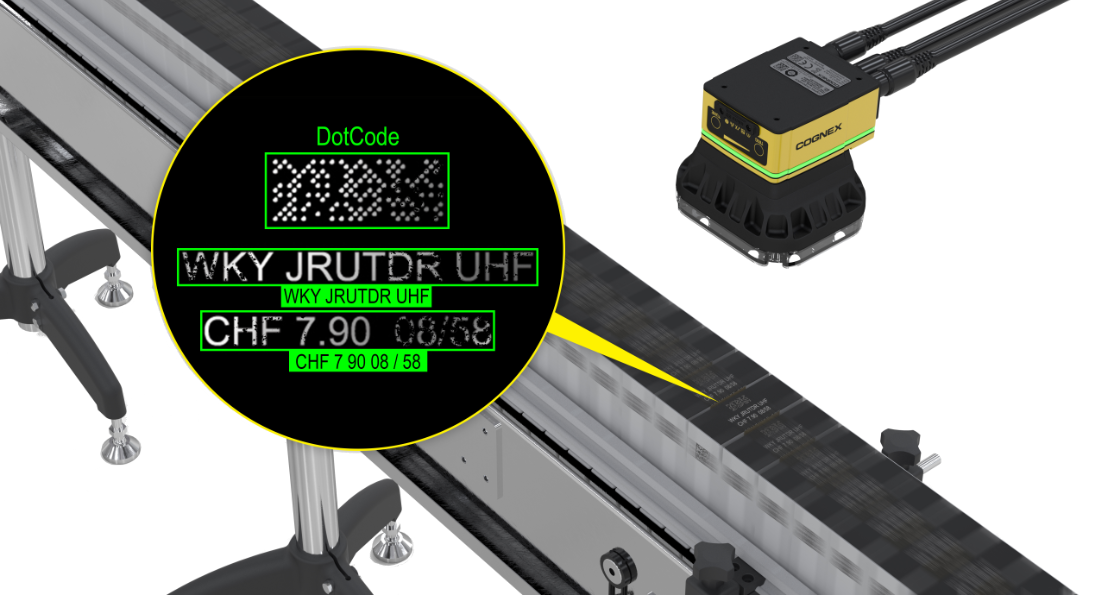

Very fast running processes, a high monotonicity or miniaturisation make automated inspections necessary. A non-contact 100% inspection is possible even for high quantities, including digital documentation and traceability.

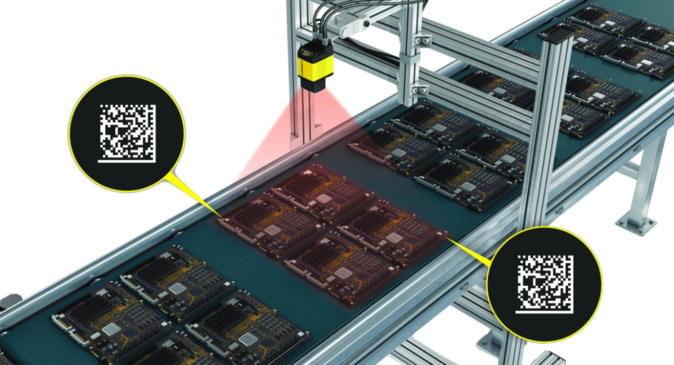

Image processing systems control product flows, e.g. by recognising properties and processing products accordingly. Production steps are also checked for completeness, incomplete products can be detected at an early stage and rejected.

Possibilities of modern image processing

As a final check, machine vision systems ensure completeness or quality, e.g. before products are packed or delivered.

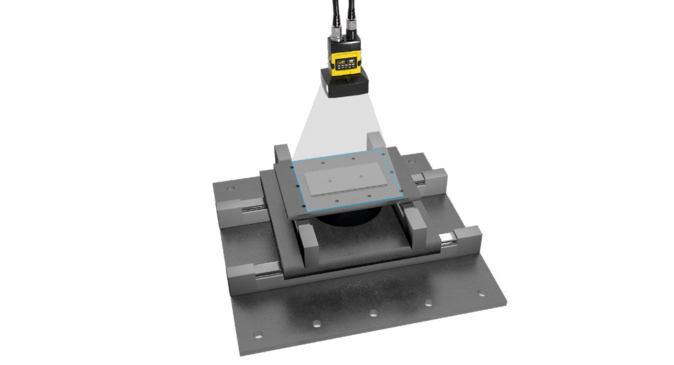

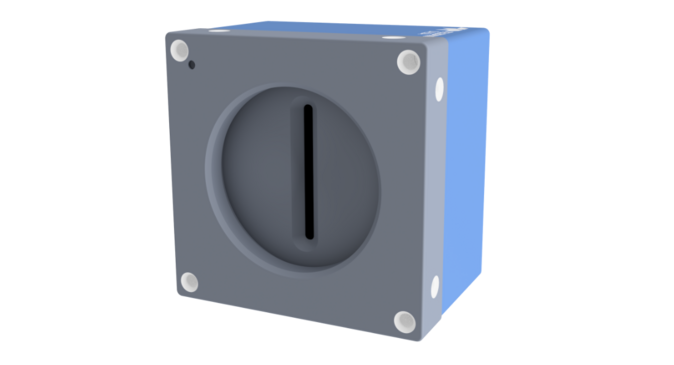

Due to the rapid further development of the technology, for example with 3D acquisition, new inspection tasks can be solved. With hyperspectral imaging, several images are taken of a scene in different wavelength ranges. Combined, these images provide a greater depth of information. We would be happy to accompany you on a journey into the world of possibilities of modern image processing.