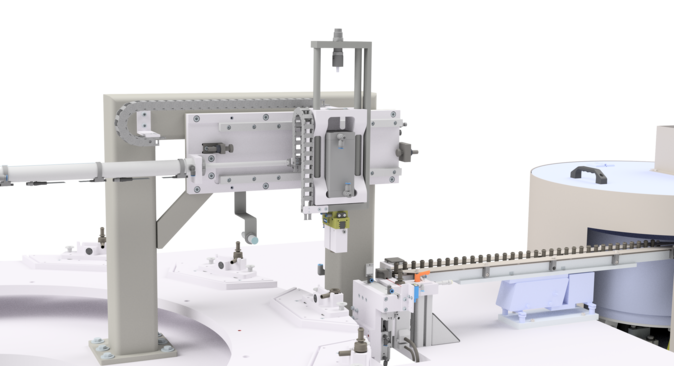

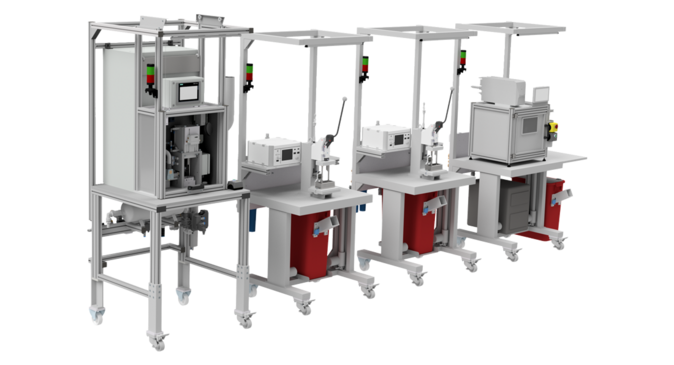

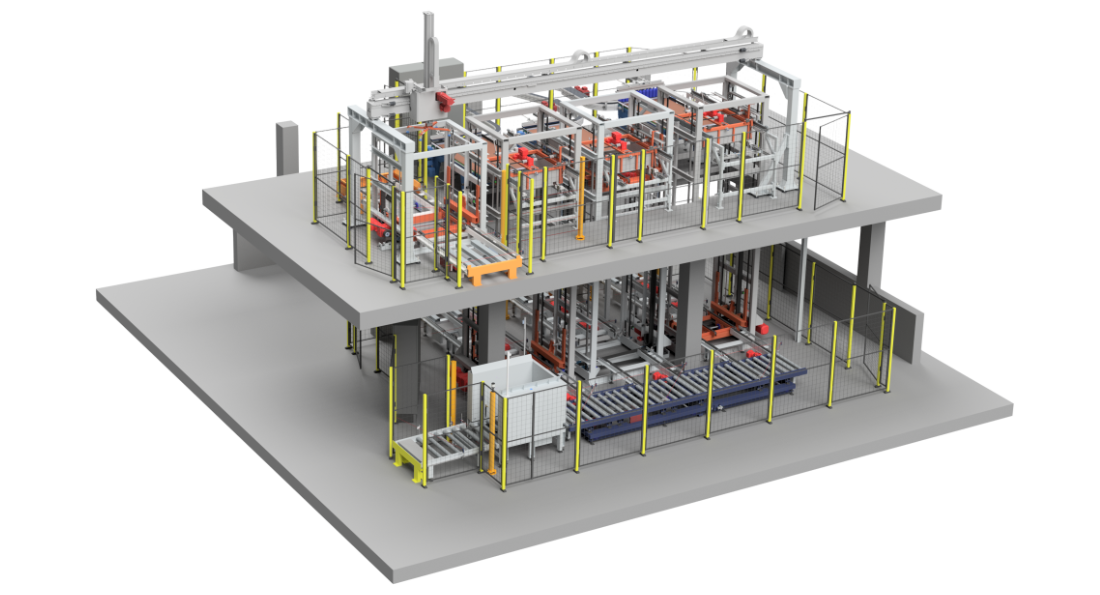

High quantities

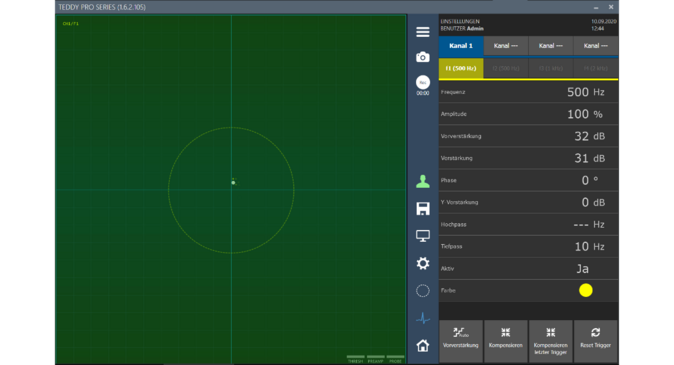

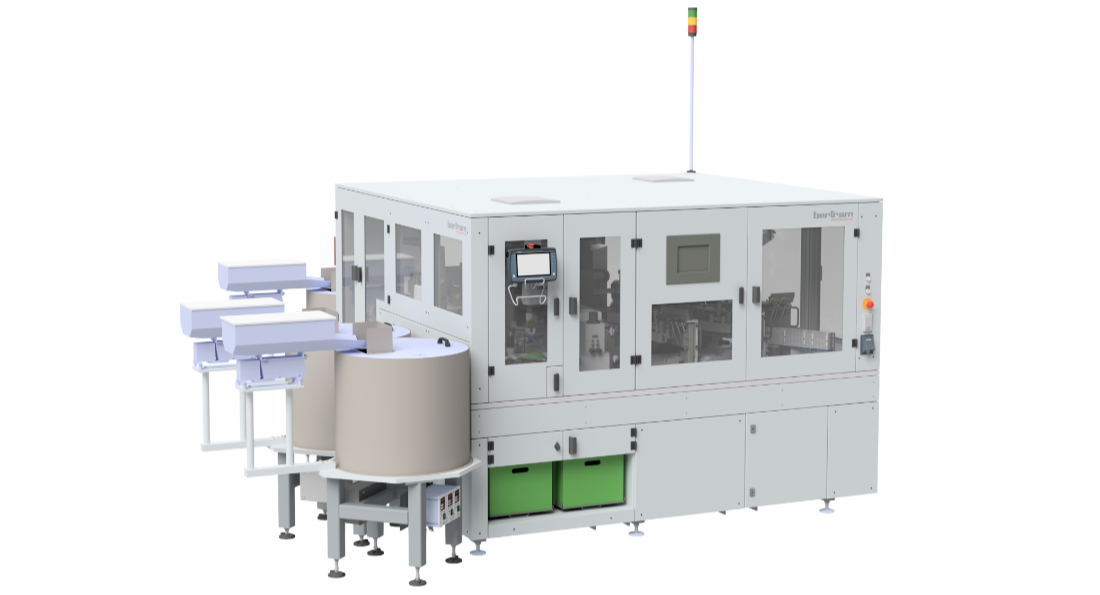

Fully automated assembly systems are ideal for high volumes. At the same time, IIoT solutions today offer better possibilities for customisation than a few years ago. For example, image recognition makes it possible to adapt to different types of components in a system without the need for retooling. The decisive factor is the networking and storage of parameters for the individual work steps. You have an overview of the entire unit using the controls we have developed.

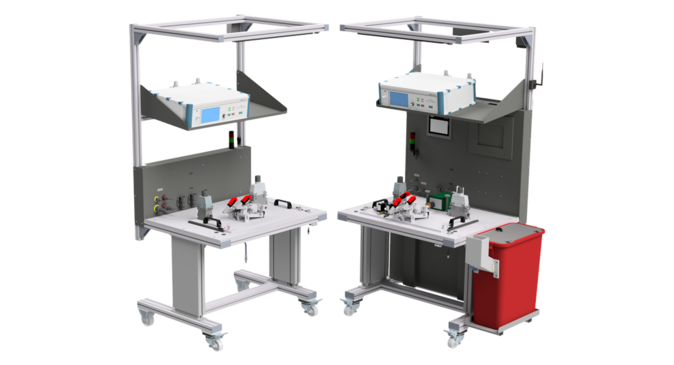

Wide range of technologies

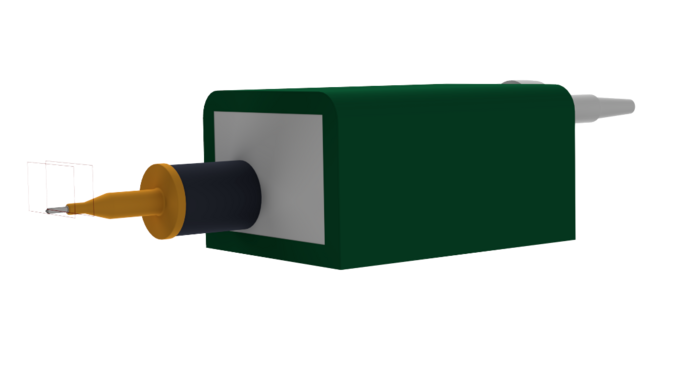

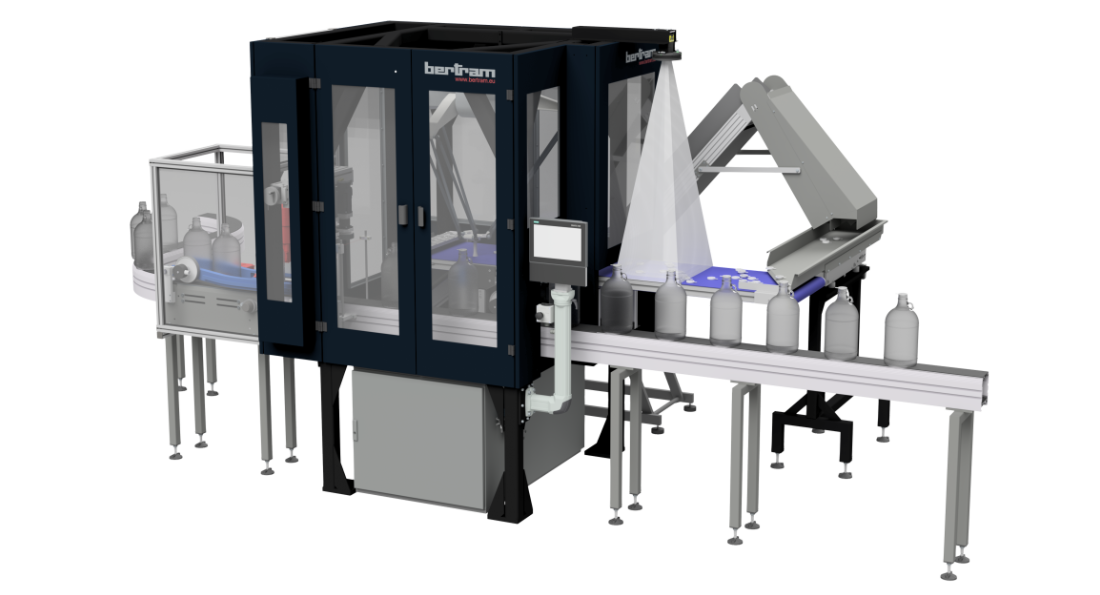

We apply a wide range of technologies: from image recognition to robots, innovative markings or efficient inspection modules. Interfaces such as ProfiNet or IO-Link are used to exchange data in the individual modules and with other stations in the production chain.

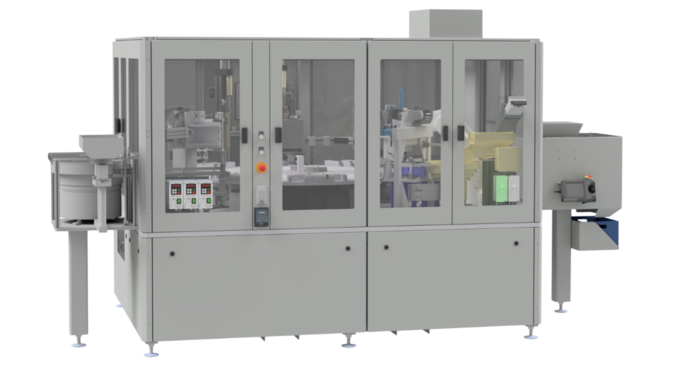

Assembly

For large quantities of the same or similar parts, a fully automatic machine is the most economical solution. In the fully automatic machines from Bertram, the individual parts are fed in station by station and assembled into one unit. Joining processes such as friction or laser welding can be integrated.

The assembly is then checked for function, labelled accordingly and filed. Missing parts are rejected and all relevant production data is documented.

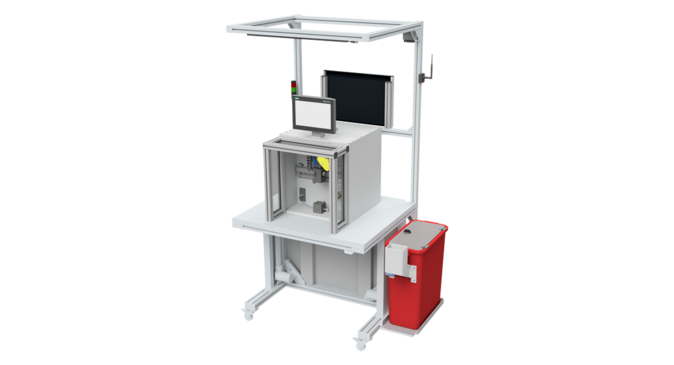

Minimisation of set-up errors

Where in the past the retooling of fully automatic machines was often time-consuming, today, retooling errors are minimised through the identification of change parts by means of RFID, and optical inspections with flexible camera systems are used that do not have to be retooled.