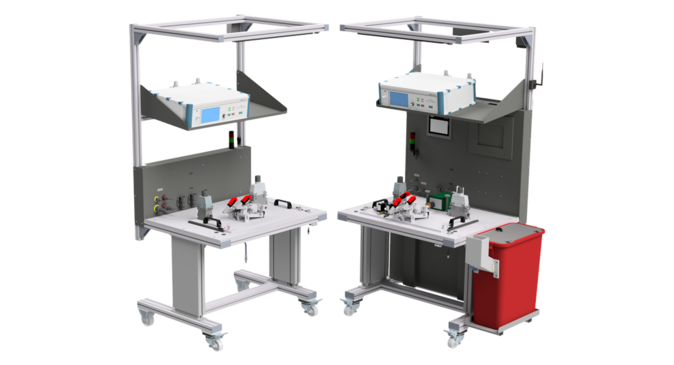

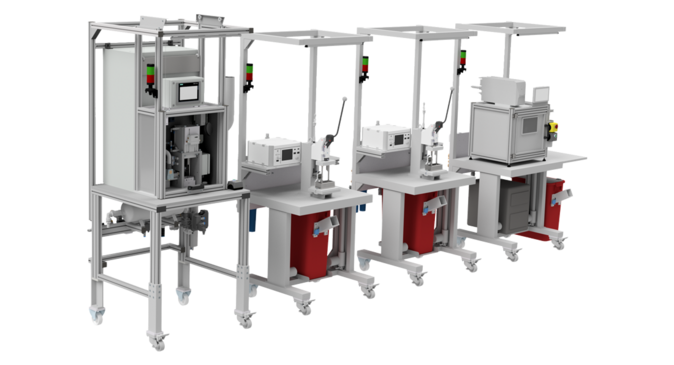

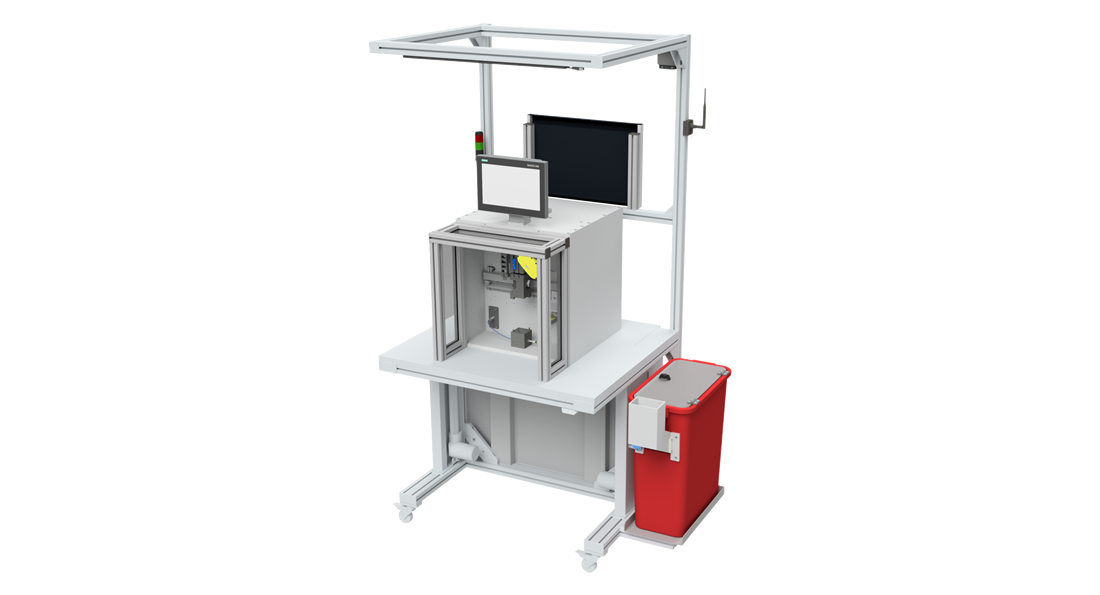

Good middle ground

Semi-automatic or partially automated manual workstations are often a good middle ground. The initial budget is significantly lower than the volume required for fully automatic machines, and at the same time the product quality can be significantly increased by automating critical work steps. Ergonomics and work safety, together with an increase in productivity, play the central role in the design of the unit.

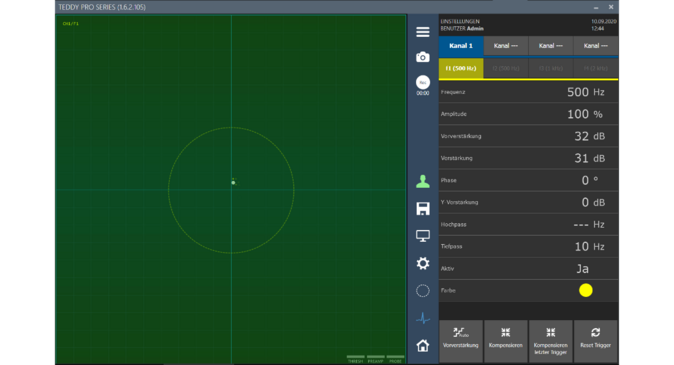

Additional growth potential

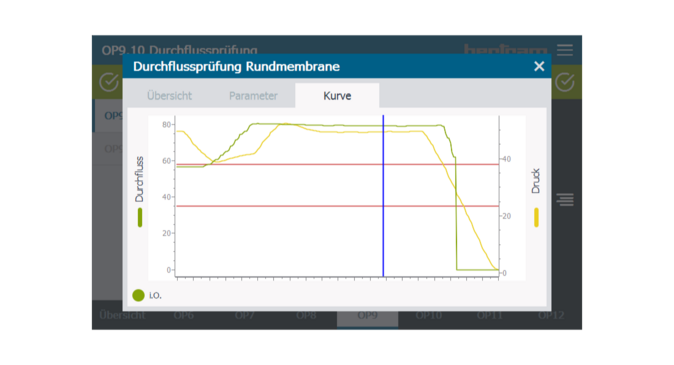

Through human-machine interaction as well as through integration into the IT structure of the production plant, we raise additional potential for increasing productivity. Examples of this are digital counting units, light signals or screens with information on the workpiece or handling.

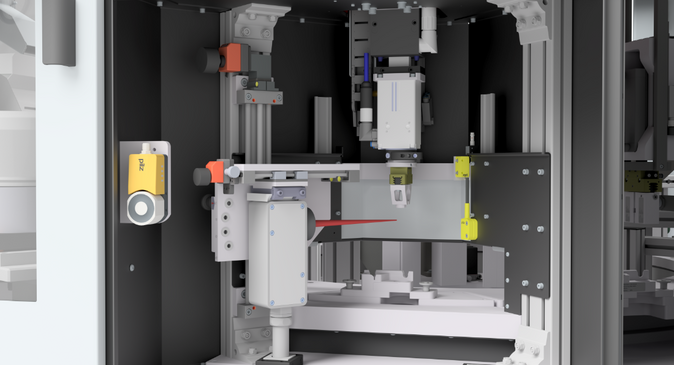

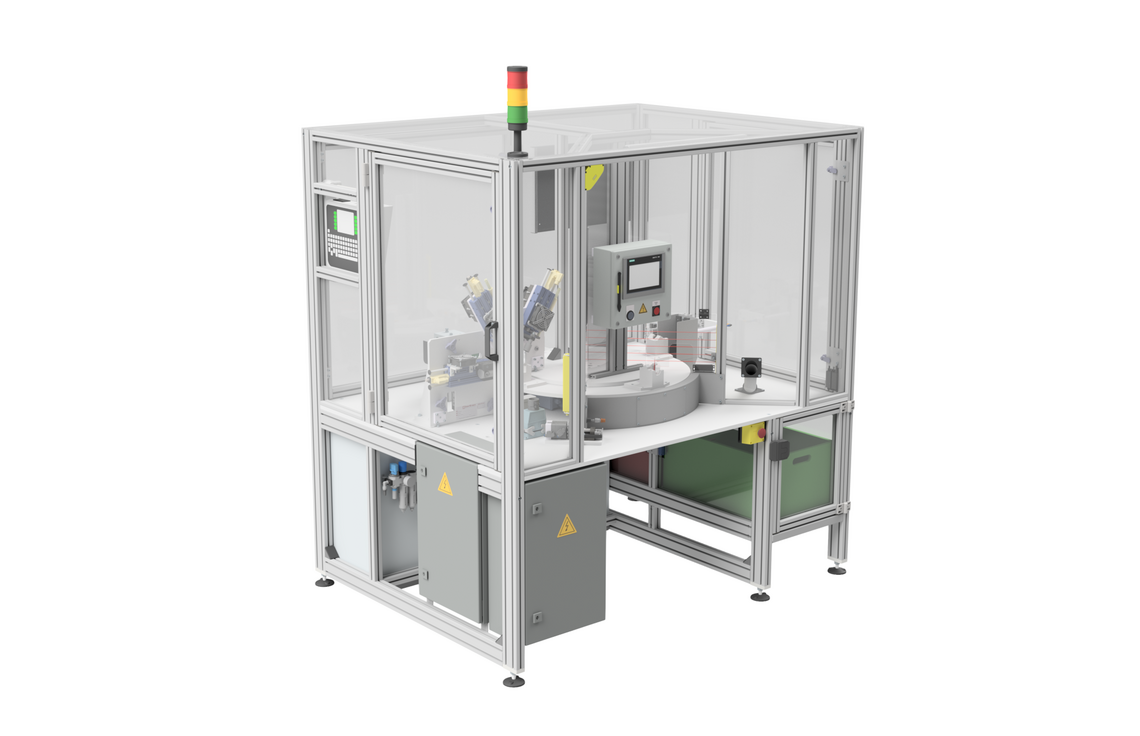

The combination of human eye and hand is technically only possible with great effort. Therefore, semi-automatic machines, i.e. systems in which automatic process steps are combined with manual parts handling, often represent an economic compromise solution.

Low investment

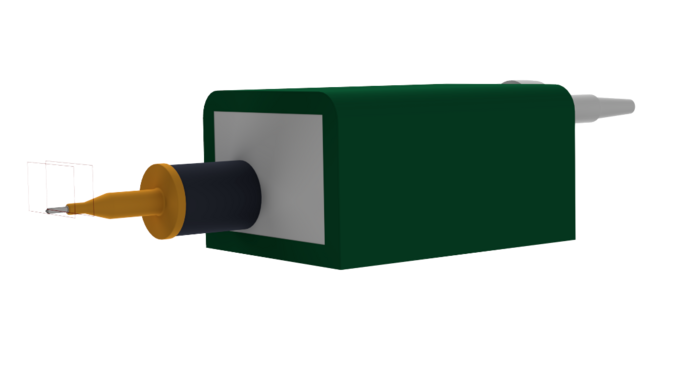

In the process, quality-relevant assembly and inspection tasks and simple handling steps are automated. This avoids errors and rejects and increases performance.

In contrast, the precise positioning of bulk material in a machine requires a component-specific device, which is not required here.

In addition to the lower investment, another advantage of the semi-automatic machine is that it is easier to reuse for other parts once a component has been discontinued.